Arc Flash Study

Mitigate Risk and Avoid Unplanned Downtime with an Arc Flash Study

Every 30 minutes, an electrically induced injury occurs in facilities across Europe and the United States.¹ Some of these injuries are due to sudden arc flash.

This phenomenon occurs when a flashover of electric current leaves its intended path and travels through ionized air from one conductor to another. It can be caused by dust, accidental touching, material failure, corrosion, and many other factors. The results can be serious injury and even death.

Our arc flash hazard assessment services help reduce the risk of injury should an incident occur in your facilities. Arc flash study assessments also help you protect your people, minimize costs, and maintain compliance with credentialing authorities.

Positive outcomes of an arc flash study with SEAM Group:

- Reduce arc flash and fire risk.

- Protect people and assets.

- Ensure compliance with EN 50110-1 Safe work practices, 89/391/EEC OSH Framework Directive, EN 61482 Live working – Protective clothing against the thermal hazards of an electric arc flash

Safety

Identify potential safety risks to protect the integrity of your assets and prevent safety events.

Risk & Compliance

Protect your people and operations while ensuring compliance with inspections and assessments.

Maintenance

Bolster the efficiency of your maintenance team by identifying issues and prioritizing repairs.

How Our Arc Flash Hazard Assessments Work

As part of a full asset management strategy, our expert team will perform the following elements of an assessment:

- Assess on-site electrical systems equipment

- Determine available short circuit current and interrupting time of each device.

- Calculate the largest incident energy at the specified working distance.

- Calculate the arc flash boundary and hazard risk category.

- Complete a protection device coordination study.

- Prepare recommendations for reducing incident energy.

- Determine the maximum arc flash hazard and express that in calories so you can choose PPE as per EN 61482 Live working requirements.

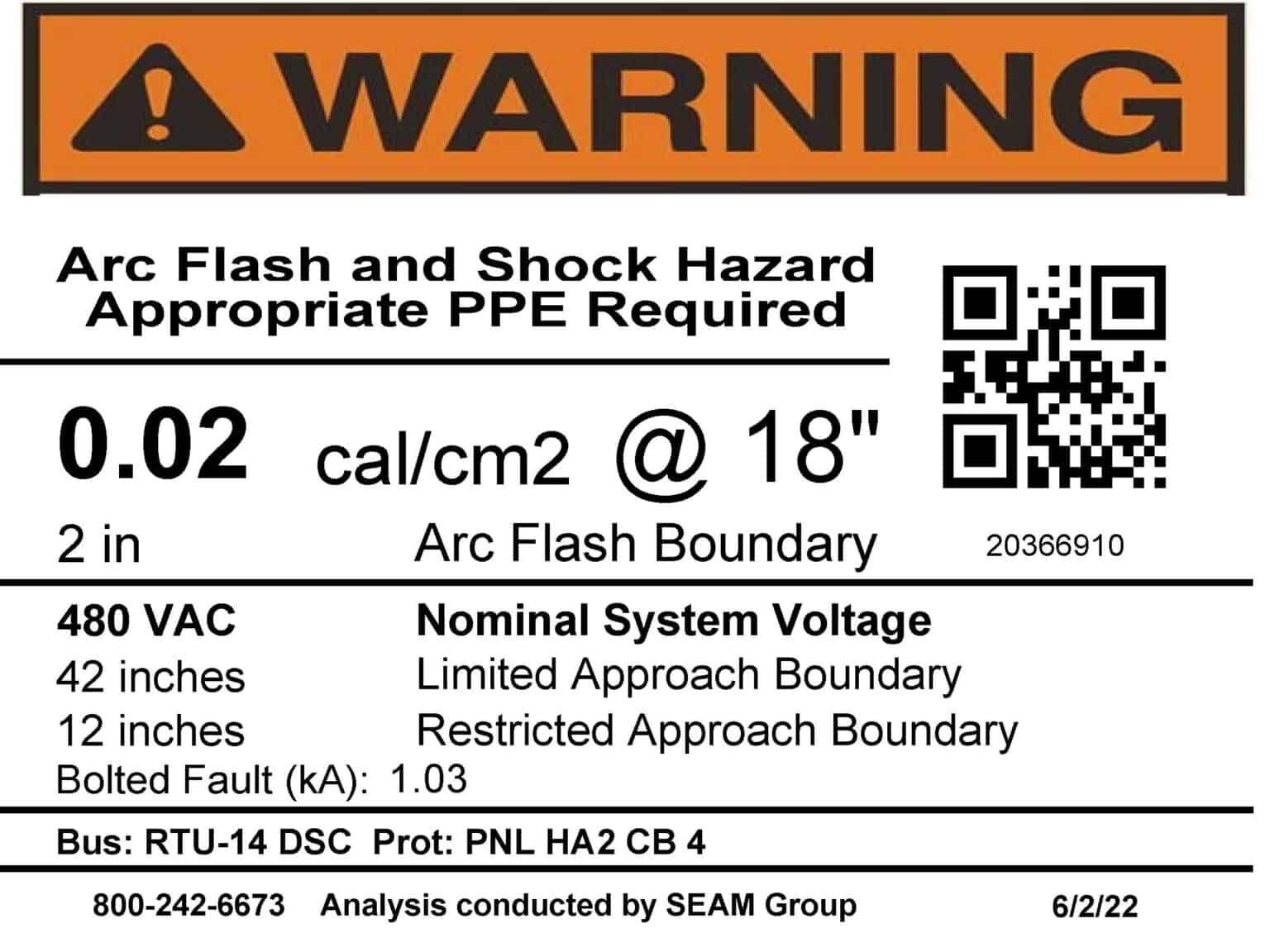

- Document results and generate labels for the equipment

Arc flash hazard assessments are critical to an overall safety and compliance program per the EN 50110-1 Safe work practices requirements. Conducting them frequently, even if only to validate existing calculations, improves employee safety by providing location-specific safety information to employees and contractors.

Our trained, engineer-certified employees conduct your arc flash hazard assessment with high expertise, adhere to all safety procedures, wear appropriate PPE, and communicate with you on progress.

A scalable solution for any industry

No matter your industry, SEAM Group can enhance your safety, reliability, and maintenance capabilities.

Uptime, safety and productivity issues can have negative effects on your overall operations, team performance, and reputation in the marketplace.

Companies in this industry have been hit hard by the pandemic and require robust safety, reliability, and maintenance plans to ensure uptime of facilities in order to meet increasing customer demands.

As the world turns digital-first, maintaining the safety and reliability of key equipment and data centers is the key to meeting customer uptime and SLA requirements.

Compliance, reliability, safety, and speed to market are key components for success in the Life Sciences space. Through our unique mix of services and solutions, SEAM Group has you covered.

The property management sector requires comprehensive inspection and maintenance services to deliver key outcomes such as compliance, reduced risk of fire or electrical outage, and enhanced customer experience to drive occupancy rates.

A reliable, safe and risk reduced operations is the key to running a successful oil and gas business. Let SEAM Group solutions drive you to these outcomes.

Your employees and guests deserve confidence in the safety, reliability, and maintenance of your facilities. Give it to them with our expertise.

Insurance companies should be focused on reducing their overall risk exposure to ensure customer satisfaction and team effectiveness.

With hundreds and sometimes millions of people depending on clean water and well-functioning power, the overall quality is key.

From charging station reliability to pre-build site plan assessments, we are experts in ensuring the optimal utilization of your equipment.

The SEAM Group Difference

Collaboration and Partnership Defined

More than a vendor, SEAM Group functions as a strategic advisor to meet you where you are and take you where you need to be. We uncover quick wins, while also developing and managing long-term programs to help you exceed ongoing safety, reliability, and maintenance goals.

Related Content

Taking a Deep Dive into the World of LOTO

Article Originally Featured in Occupational Health & Safety (OH&S) Author: Bret Bevis, SEAM Group Program Manager – Infrared & ViewPoint Procedures must keep pace with

NFPA 70E® Training Considerations to Move Electrical Workplace Safety Forward

To protect employees from electrical-related injuries, the National Fire Protection Association (NFPA) has developed the Standard for Electrical Safety in the Workplace® known as NFPA

Developing a Safer, More Effective Lockout/Tagout Program

Energy sources such as electricity, chemical, pneumatic, hydraulic, mechanical and many others can be hazardous to workers. During the servicing and maintenance of machines and