Running a care home means you face unique challenges that require stringent safety measures to ensure the well-being of your residents and employees. Utilising infrared thermography inspections can help you detect potential hazards early and keep your residents and staff safe.

Improving Safety

Infrared thermography improves safety by enabling the detection of potential hazards in electrical and mechanical systems before they lead to failures, accidents, or dangerous conditions. By identifying issues such as overheating, poor connections, or insulation breakdowns, infrared thermography helps prevent safety incidents and enhances overall workplace safety, in the following ways:

1. Early Detection of Electrical Faults

- Impact: Electrical equipment failures, such as loose connections, overloaded circuits, or insulation degradation, can lead to fires, explosions, or electric shocks.

- Benefit of Infrared Thermography: Infrared thermography identifies hot spots in electrical systems that are not visible to the naked eye. Detecting these issues early, repairs can be made before they escalate into dangerous situations, reducing the risk of electrical fires and other hazards.

2. Non-Invasive and Safe Inspections

- Impact: Traditional methods of inspecting electrical or mechanical systems can require shutdowns or physical contact with equipment, exposing workers to risks such as electric shock, arc flashes, or injuries from moving parts.

- Benefit of Infrared Thermography: Infrared thermography inspections are non-contact and can be performed while equipment is operating, allowing technicians to safely assess systems without interrupting production or exposing themselves to danger. This enhances worker safety by minimizing physical interaction with potentially hazardous equipment.

3. Reducing the Risk of Fire and Explosions

- Impact: Undetected electrical faults and mechanical overheating can lead to fires or explosions, putting both employees, residents and properties at risk.

- Benefit of Infrared Thermography: By identifying overheating or faults in electrical panels, transformers, wiring, and other critical equipment, thermography reduces the risk of fire or explosion. Proactively addressing these issues before they escalate helps maintain a safer environment for both workers and assets.

4. Enhancing Worker Protection from Arc Flash Incidents

- Impact: Electrical faults can cause arc flashes—dangerous bursts of energy that can result in severe burns, injuries, or fatalities.

- Benefit of Infrared Thermography: By detecting overheating and electrical faults that may lead to an arc flash, thermographic inspections help reduce the likelihood of such incidents. This proactive approach enhances the safety of employees who operate, maintain, or are in close proximity of electrical equipment.

5. Reducing Human Error

- Impact: Traditional inspection methods may miss hidden issues, leading to potential failures or safety incidents due to human error.

- Benefit of Infrared Thermography: Infrared thermography provides objective, real-time data on equipment conditions, reducing the chance of human error in detecting faults. The thermal images provide clear, visual evidence of issues that need attention, improving the accuracy of safety assessments.

Conclusion

Infrared thermography significantly improves safety by detecting hidden electrical and mechanical issues before they become serious hazards, reducing the risk of fires, explosions, equipment failure, and workplace injuries. It offers a non-invasive, reliable method of identifying potential safety risks, ensuring that preventive measures can be taken promptly to protect workers, equipment, and facilities.

Reducing Energy Costs and Reducing Carbon Footprint

Infrared thermography inspections can significantly help reduce energy consumption and carbon emissions by identifying inefficiencies in energy use and enabling targeted improvements.

Here’s how thermography inspections contribute to energy efficiency and environmental sustainability:

1. Electrical System Efficiency

- Detecting Overloaded Circuits: Overloaded electrical circuits generate excess heat, which is a sign of inefficiency. Thermography can detect these hot spots, allowing for corrective action that can improve electrical system efficiency and reduce unnecessary energy use.

- Improving Electrical Connections: Poor electrical connections can result in increased resistance and energy loss. Infrared inspections help identify and fix these connections, leading to more efficient energy use and lower carbon emissions.

2. Reducing Carbon Emissions

- Lowering Energy Demand: By improving the efficiency of residential buildings and care homes electrical systems, infrared thermography helps reduce overall energy demand. Lower energy consumption leads to reduced carbon emissions, especially if the energy comes from fossil fuels.

- Supporting Renewable Energy Integration: Efficient energy use makes it easier to meet energy needs with renewable sources, further reducing the carbon footprint.

3. Sustainable Maintenance Practices

- Predictive Maintenance: Regular infrared thermographic inspections support predictive maintenance, allowing for the timely repair of equipment before it becomes inefficient. This proactive approach reduces energy waste and extends the life of equipment, contributing to overall sustainability.

- Minimizing Waste: Efficiently operating systems reduce not only energy waste but also material waste and associated emissions, as fewer resources are needed to maintain optimal operations.

Conclusion

Infrared thermography inspections play a vital role in reducing energy consumption and carbon emissions. By identifying areas where energy is wasted and enabling corrective measures, these inspections contribute to more sustainable operations and help organizations meet energy efficiency and environmental goals. This not only benefits the bottom line by lowering energy costs but also supports broader efforts to combat climate change by reducing greenhouse gas emissions.

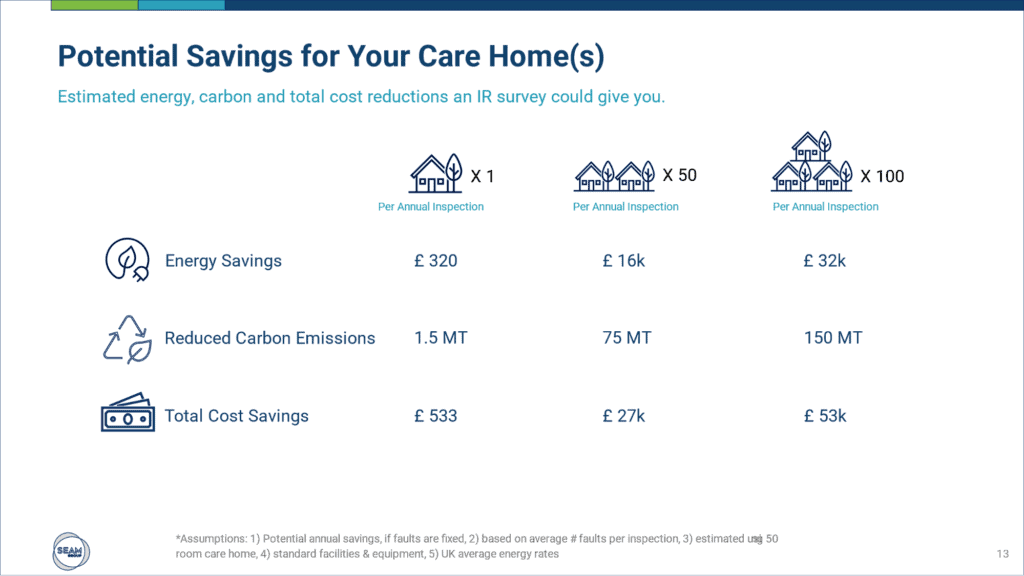

SEAM Group Experience and Predicted Savings

SEAM Group have been supporting care homes for over a decade and are proud of our results to date. We have used this experience to develop the following predictions for energy costs and carbon emission savings that care homes could benefit from, by utilising infrared thermography inspections:

Steps to Implement Infrared Thermography Inspections in Your Care Home

Implementing thermographic inspections involves several steps to ensure the process is effective and beneficial for your residents, staff, and business as a whole:

- Establish a Regular Inspection Schedule: To ensure ongoing safety, set up a schedule for inspections across your care home(s). We recommend conducting infrared thermography inspections on an annual basis.

- Hire a Professional: Certified professionals use the latest technology and are trained to interpret thermal images accurately. Our expertise guarantees reliable inspections and actionable insights, ensuring your care home meets industry standards and regulatory requirements.

- Conduct the Inspection: We will document findings with detailed thermal images and notes to help track the condition of assets over time. SEAM Group stores all inspection findings, images, cost, and carbon saving data on our patented software ViewPoint.

- Report and Act on Findings: We create comprehensive reports with thermal images, descriptions of identified issues, and recommendations for corrective actions. We share these reports with management to ensure prompt and effective responses.

- Integrate into Maintenance Plans: Inspection findings inform routine maintenance and preventive measures. Incorporating these insights into maintenance plans helps proactively address potential issues before they escalate.