Overview

A multinational technology company offering global e-commerce, cloud computing, digital streaming, and artificial intelligence requested help improving safety and operational performance at its delivery stations.

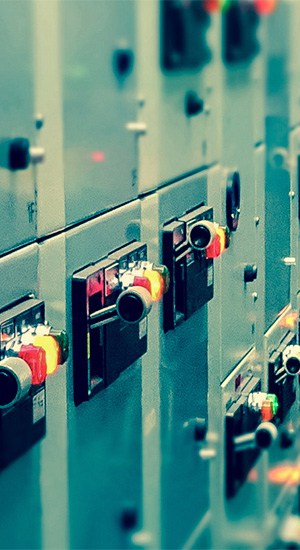

The company partnered with SEAM Group to perform infrared thermography, arc flash studies, and lockout/tagout (LOTO) services to improve safety, maintain reliable and efficient operations, and achieve customer satisfaction.

Solution

SEAM Group provided a comprehensive electrical safety program for their global e-commerce facilities.

Infrared thermography

- Review each facility’s electrical system to identify thermal and visual compliance problems. Inventory all inspected assets and establish a baseline for historical trending.

- Electrical panel service by qualified electricians to safely open and close each electrical asset included in the infrared inspection.

- On-demand maintenance by qualified electricians to address all thermal and compliance problems found during the infrared inspections.

Arc flash studies:

- Perform an on-site assessment of electrical equipment.

- Uncover correctable issues within the electrical distribution system.

- Determine each device’s available short circuit current and interrupting time.

- Calculate the highest incident energy at the specified working distance.

- Conduct a protective device coordination study.

- Offer recommendations to reduce incident energy.

- Determine the required personal protective equipment (PPE) level.

- Document the results and generate labels for the equipment.

Lockout/Tagout:

- Develop energy control procedures (ECP) and identify appropriate lockout and tagout devices.

- Train workers on hazardous energy and lockout tagout procedures, policies, and equipment.

- Conduct periodic audits to verify ECPs accuracy and ensure that employees follow proper energy isolation of equipment to perform servicing and maintenance.

Results

- By leveraging ViewPoint® infrared inspection reporting capabilities, the client spotted and prioritized issues that could lead to unplanned downtime.

- The client successfully launched a variety of new delivery stations safely and on time by reducing arc flash exposure for its employees as they troubleshooted and repaired equipment.

- A proper lockout/tagout program ensured compliance with applicable regulations and protected employees from the unexpected energization of assets during service and maintenance activities.

- Due to the success of the relationship between the client and SEAM Group, the scope of services grew to include Switchgear Low Voltage Preventive Maintenance (LVPM).

Share

Results

Because the client company used SEAM Group’s infrared technology to spot potential downtime issues, they achieved increased uptime. Furthermore, the mitigation provided for arc flash hazards enabled the company to reduce arc flash exposure, allowing employees to safely troubleshoot and repair equipment as needed. As a result, the client company successfully launched a variety of new delivery stations safely and on time.