“NFPA 70B standard for electrical equipment maintenance, originally, published in 1973 as a recommended practice, was elevated to a standard in January 2023.”

From should do, to shall do. is your electrical maintenance program in compliance with the new NFPA 70B standard?

Why does this change affect you? Because you are responsible for the safety of your employees and the reliability of your electrical equipment.

How do you get started? We will walk you through four steps for safety and compliance success.

It’s no secret that electrical maintenance is critical to a successful organization’s risk-management strategy. The outcomes speak for themselves:

- Reduce risk of fires and electrical injuries

- Improved safety for workers and occupants

- Increased equipment reliability

- Extended equipment life

- Reduced maintenance costs

Your electrical maintenance program’s maturity and understanding of OSHA, NFPA, federal, and state requirements will significantly impact your ability to maximize the intersection of safety, reliability, and maintenance.

You are responsible for the safety of your employee and the reliability of your electrical equipment.

NFPA 70B is a standard for electrical equipment maintenance to safeguard your people, property, and processes from the risks of electrical equipment failure, breakdown, or malfunction. This standard also provides a means to establish a condition of maintenance of electrical equipment and systems for safety and reliability.

NFPA 70B guides the preventive maintenance of electrical systems and equipment, covering a wide range of topics, including:

- Inspection and testing

- Cleaning and lubrication

- Repair and replacement

- Safety procedures

For the NFPA 70B standard to yield its intended benefits, you must follow the NEC code for equipment installation and the NFPA 70E standard for electrical safety in the workplace.

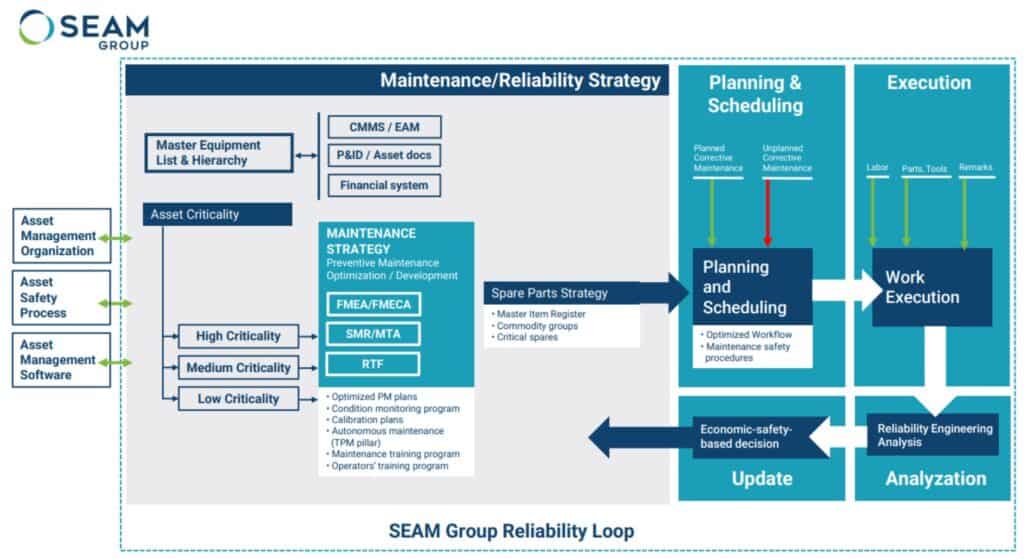

A roadmap for your maintenance and safety alignment journey.

Whether you use a computerized maintenance management system (CMMS) or track and manage maintenance plans and activities on spreadsheets, we can help evaluate and optimize your maintenance strategy for compliance and sustained success. The journey begins with the following four steps:

- Developing or updating your electrical equipment maintenance plan

- Training your employees

- Implementing your maintenance strategy

- Optimizing performance

Develop or update your electrical maintenance program, starting with two essential prerequisites:

- Update your primary asset list and make sure you have updated single-line drawings. These documents will serve as key references for your system.

- Physically assess your equipment to determine the current condition of your energized assets and categorize them following NFPA 70B criteria. This critical step will help inform your maintenance intervals decisions.

Once you have completed these prerequisites, you can develop your maintenance strategy and schedule considering the following factors:

- Your risk-based management priorities

- The criticality of your equipment

- The manufacturer’s recommendations

- The results of risk assessments

Train your people on the NFPA 70B standard implications to your facility and electrical equipment; and the intersection with NFPA 70E for safe work practices.

Whether you rely on in-house personnel, outsourcing, or a hybrid model, implementing your electrical maintenance plan is where your disciplined approach pays off.

- Stick to your electrical maintenance plan and priorities

- Engage your safety and maintenance leaders with shared KPIs and goals

- Choose partners who can provide consistent service and digital reports for all your facilities

Track maintenance activity, progress, and issues to avoid unplanned disruptions, drive continuous improvement, and optimize safety and maintenance performance.

From consulting to field services, power your plan with our technology and comprehensive solutions

Our mission is to create safer, more reliable work environments. Leaders like you partner with our global team of experts to align safety, reliability, and maintenance so their people and business can thrive.

How do we help? We bring comprehensive solutions, a flexible approach, and our unique ViewPoint® technology solution to tie it all together.

- Reliability consulting and engineering

- Training solutions: Live webinar, self-paced on-demand, and onsite

- Safety and maintenance program evaluations and roadmaps

- Hazardous energy control programs and lockout/tagout procedures

- Arc flash studies, report reviews, and field support

- Switchgear preventive maintenance

- Predictive maintenance field services, including infrared thermography, vibration, ultrasound, and motor and oil testing

ViewPoint brings together safety-critical information from your LOTO and arc flash programs and lets your people easily access it at the point of work via QR code scanning.

The insights you gain through ViewPoint empower you to make data-informed decisions and show your predictive maintenance program’s impact on energy savings, carbon reduction, downtime avoidance, and more.

We are ready to embark on this journey with you. Let’s talk about getting to the place where safety and uptime align.

Jay Smith

Director – Electrical Safety Services

As Director of Electrical Safety Services at SEAM Group, Jay is our resident expert for electrical safety solutions. Jay partners with our clients to develop relevant solutions that integrate safety, maintenance, and reliability so that they can get optimized performance from their arc flash, lockout/tagout, infrared, and electrical maintenance investments. For over two decades, Jay has helped thousands of clients improve workplace safety and performance by implementing industry electrical safety and maintenance standards. Jay is known nationally for his expertise with arc flash and NFPA 70E and speaks at numerous national conferences and corporate safety summits.